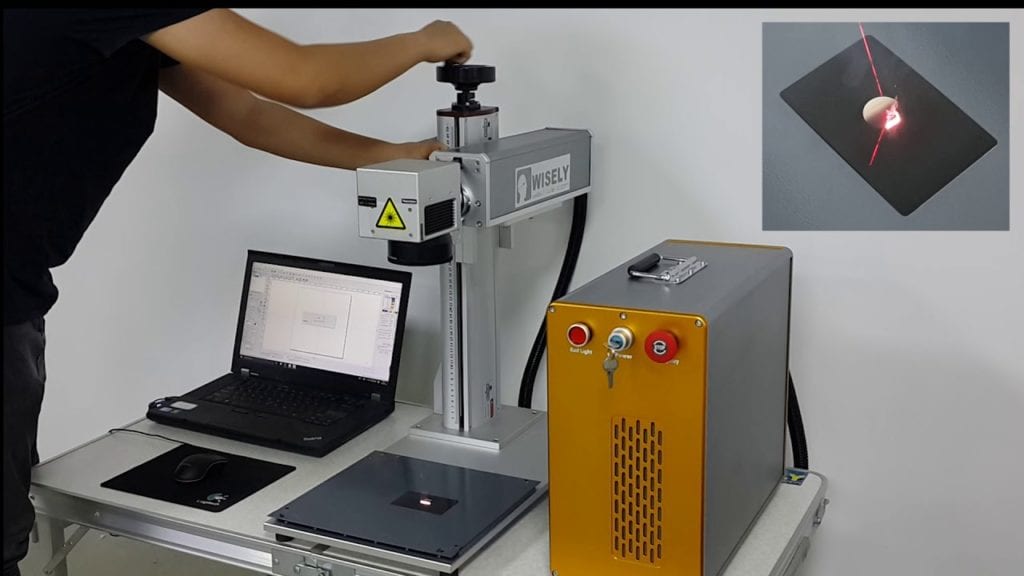

The new technologies have created many business opportunities. One of the sophisticated technologies that are used by the people to venture into the business of engraving names, logos, and codes on the products is laser marking. This machine is helping people to earn huge profits by engraving logos and names on the products. Though laser technology is not new, this has gained huge popularity in marking the labels in recent times. This is overshadowing old fashioned engraving methods and doing businesses to engrave logo or names on the products with high speed using the quality marking machines.

Laser marking is the process of focusing the laser light on the specific point or pattern in a medium. The energy that is released from the laser would create an accurate marking on the product. However, the depth at which the marking is done and the color of the marking can be controlled. The laser marking machine will serve many businesses. Be it you want to start a jewelry business or automotive parts manufacturing business, having laser marking technology will create uniqueness for your products.

Few of the customers you can serve by starting the business using laser marking machine include:

Jewelry: It is not a new thing to create personalized jewelry. When you customize the jewelry, it gives a new appeal and flair to the jewelry. Earlier, the customized jewelry was made with hands. Though the methods that were used were standard, it used to consume a lot of time. However, using the laser marking machine, you can engrave the customized pieces at a brisk pace. You can create a huge volume of customized jewelry with this marking machine.

According to heatsign.com, there are two techniques used in the process of engraving. There include ablating, which will vaporize a thin layer of material surface and annealing, which changes the color of the material without removing the material. This machine will let the jewelry artisan customize jewelry in a matter of a few seconds. This machine gives ample freedom to the artisans to come up with new designs. These are accurate and create appealing digital designs. The wedding bands are easy to execute using this machine where the fingerprints or handwritten names of the couples can be marked on the rings.

Automotive parts: Quality and reliability are two important things that the automotive industry would need to run it successfully. Every part that has to go to the market should first pass the standard quality tests to assure the safety of customers who are using the part. There should be a reliable system in place to trace all the 20,000 parts that are used in making a car. There should be a proper marking method to make the traceability job completely automated.

This is where the laser making machine would be used. The laser marking would let you create accurate markings on the automotive parts such as radiator caps, ignition coils, etc. The automotive components are marked with serial numbers, bar codes, and QR codes using this machine briskly. This machine quickly marks the serial numbers on thousands of parts in no time. The seatbelts in the car would also be marked with traceability codes. The interior parts of the car are also labeled using this machine.

The tick marks on the speedometer, along with the buttons that are available on the windshield panel, can be marked with the help of this machine. The marking would safeguard the brand against the other fake brands that are selling the same type of products as you in the market.

The laser marking has become quick using this machine. It takes just a few seconds to put a mark on the automotive component.

Medical devices and instruments: The FDA is clear that medical devices should have a unique identification to have traceability. This will ensure the safety of patients and increase the surveillance of devices. The UDI codes should be easy to be read by humans and machines equally. The industry would need a technology that would mark the code on the devices. The laser marking machine better performs this task. This machine is used to create fine details of the serial numbers, batch numbers, manufacturer name, and production date.

The details will remain durable on every small to large items. The medical devices are using a laser marking machine to print the serial numbers and other details. There are various devices on which you see this marking include sample bottles, surgery tools, plastic cannula, etc. The marks that are made by laser do not have any chemicals and would have the ability to withstand high temperatures without getting degraded soon.

Imagup General Magazine 2024

Imagup General Magazine 2024