Electronic devices use electricity. This means they will generate heat as they work thanks to the resistance these electric currents experience as they pass around the devices. With time, this heat can become unbearable to the devices.

Think about an organization with CPUs sending instructions to thousands of devices. For such organizations operating 24 hours a day, enormous heat is bound to be produced. This can adversely affect the CPUs’ performance. Or could completely incapacitate them. To prevent such from happening, every device is installed with a heat sink.

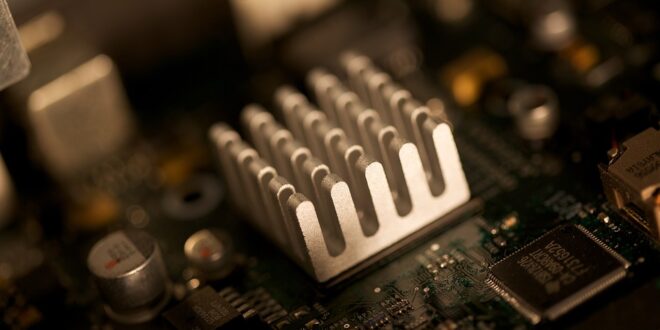

What is a heat sink?

A heat sink is a heat exchanger. The temperature regulator works passively to dissipate heat from an actively functioning electronic device. This allows the electronic device to work at optimum temperature without overheating.

Some machines give out a lot of heat that may overwhelm the heat sink. That may be the reason you still feel some machines are hot enough. To avoid such from occurring, heat sinks are sometimes used alongside transistors or optoelectronics.

This increases their ability to dissipate more heat thus cooling the device better. A lot is considered when making a heat sink. That determines how effective the coolant will perform, but we’ll look into that later in this article.

Air gaps that exist between the heat sink and spreader make it harder for the sink to work more effectively. To reduce this ineffectiveness, developers of this device use thermal paste. The thermal paste/adhesive helps to fill the gaps.

By doing so, the heat sinks become more efficient. The dissipation process is more complete and increased heat is let out. Machines are left with enough cold air to continue working effectively.

This keeps electronic devices in optimum conditions despite increased resistance.

What are heat sinks used for?

The heat sinks’ sole purpose is to regulate heat in electronic devices. In the case of CPUs, developers are still inventing very powerful and sophisticated devices. These machines consume a lot of power to operate. This is partly because they store a lot of information and feed so many computers. As a result, so much more heat is given out.

Heat sink developers are also continuing with their research to get ways through which they can enhance the sinks’ functionality. This is because there is an increasing need for heat sinks that dissipate more heat.

Heat sinks have been designed with amazing specifications to allow them to function optimally. The material used to make heat sinks is of significance. Aluminum is the most common material used to design these coolants.

This is because of the several Aluminium properties that favor the functionality of heat sinks. One of those properties is Aluminum’s good heat conductivity. This allows the heat sink to transfer as much heat as possible leaving the electronic device cool enough to perform well.

Several calculations are also done when making these heat sinks. The operating temperature of a power transistor is affected significantly by junction temperature. Power consumption and thermal resistance also play a role in all this.

To get the best position for a well-functioning heat sink, you need proper calculations of these variables. This will increase the ambient temperature under which the transistors in the electronic devices operate in.

When it comes to material, copper and Aluminum are the most popular options in the market. Costs, weight, and texture among other reasons advise people’s decisions to go either way. In most cases, developers opt for Aluminum. The metal never disappoints.

Factors that Impact Heat Sink Performance

Heat sink performance varies. Different factors play a role in these variations. Below are factors that impact heat sink performance.

1. Material

This is a very important consideration when making a heat sink. Aluminium alloys and copper are the best materials for making a heat sink. When choosing which material to be used, a lot is looked into.

If you choose Aluminium material, you can shop with providers like FONNOV ALUMINIUM. This is a leading provider in Aluminium extruded products which happens to be the best material for making durable and high-performing metals.

Aluminium is cheaper and less dense than copper. Besides, it’s corrosion-resistant as well as a good heat absorber.

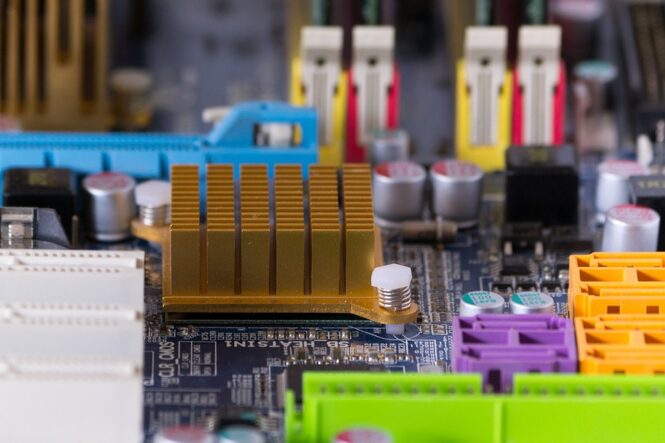

2. Heat sink fins

These are a feature of the heat sink that increase its performance. Designers use materials that have very high thermal conductivity to make more efficient heat sink fins. The fins are also designed in a special shape to make them better performers. Overall, this increases the fins’ ability to absorb more heat for dissipation.

The arrangement and shape of heat sink fins affect their overall performance. Therefore, designers work on shapes that allow maximum transfer of heat. The size and location of the heat sink fins also influence the heat sink’s performance.

3. Thermal interface resistance

Heat flow faces resistance between the die and coolant fluid. This affects the successful dissipation of heat from an electronic device. Designers, therefore, seek to enhance heat dissipation by working out the best thermal resistance ratio that will make way for the highest heat transfer possible.

How to improve the performance of the heat sink

In one ‘Do it Yourself’ forum, Mr. Lukas improved the performance of his heat sink using hydrochloric acid. He says it worked well and that it’s worth a try. The acid made the surface of the heat sink more rugged. This helps create a micro-turbulence that increases the performance of the heat sink.

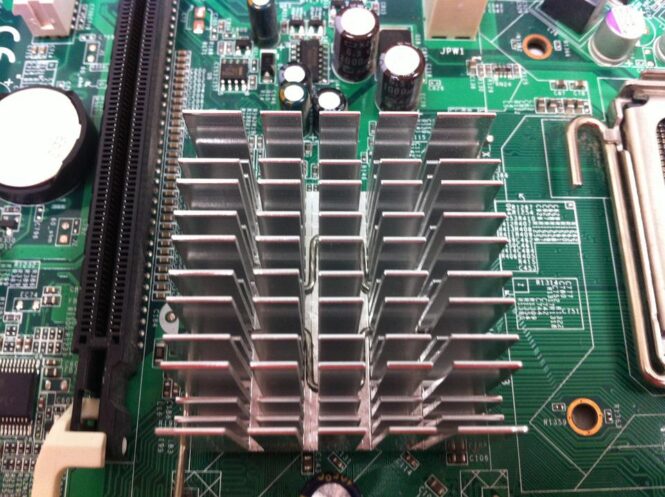

The fins in a heat sink play a major role in its performance. That explains why you should mount it in the right manner. In most cases, you should mount the fins in a vertical way for better performance.

The vertical positioning of heat sinks improves airflow. Remember that proper airflow is responsible for most high-performing heat sinks. This, it does, using low voltage. This means, that lesser heat will be produced in the process.

Some experts also advise that you reduce the size of the fan to increase productivity. Besides, you should try all you can to release the trapped air. This will allow for proper flow and your heat sink will do better than before.

Imagup General Magazine 2025

Imagup General Magazine 2025