In today’s fast-paced manufacturing industry, accuracy and efficiency are everything. From aerospace components to medical instruments, the demand for parts that meet exact specifications has never been greater.

This is where precision machining plays a vital role, offering unparalleled accuracy, consistency, and reliability in the creation of high-performance components. As technology continues to evolve, precision machining has become the backbone of industries that rely on tight tolerances and flawless production standards.

What Is Precision Machining?

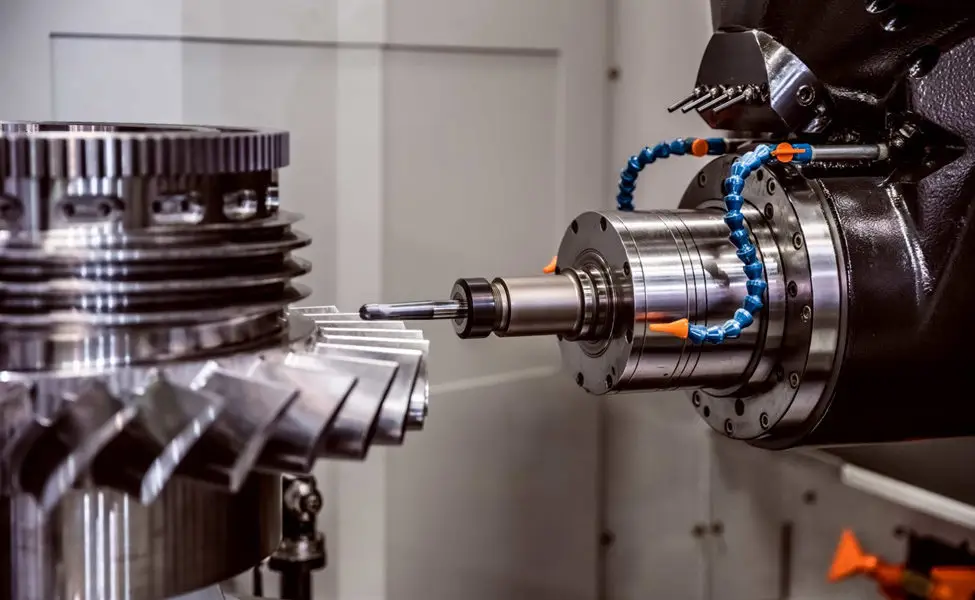

Precision machining is the process of shaping raw materials into finished components using computer-controlled machines and specialised tools. These machines, such as CNC (Computer Numerical Control) mills, lathes, and grinders, are capable of achieving extremely fine tolerances measured in micrometres. Unlike traditional manufacturing methods that rely heavily on manual operation, precision machining utilises advanced software and automation to ensure consistency and repeatability.

The materials used in precision machining vary widely, from metals like aluminium, titanium, and stainless steel to engineering plastics and composites. The versatility of the process allows manufacturers to produce parts that fit seamlessly into complex systems, making it essential in industries where precision is non-negotiable.

Applications Across Multiple Industries

Precision machining is used across a broad range of sectors. In the aerospace industry, it ensures that aircraft parts such as turbine blades, landing gear, and engine components meet stringent safety and performance requirements. Even the smallest imperfection in an aircraft component can have catastrophic consequences, which is why precision machining is indispensable in this field.

In the medical sector, precision-machined components are used to create surgical instruments, orthopaedic implants, and diagnostic devices. These products require smooth surfaces and exact measurements to function properly and safely.

The automotive industry also relies heavily on precision machining to produce parts like pistons, valves, and transmission components. With increasing demands for efficiency and performance, the ability to create lightweight, durable, and accurate parts has become essential.

The Benefits of Precision Machining

One of the main advantages of precision machining is its ability to deliver exceptional accuracy. Using advanced software and automated tools, manufacturers can produce parts with incredibly tight tolerances, ensuring every component fits perfectly into larger assemblies.

Another benefit is consistency. Once a design has been programmed into a CNC machine, it can reproduce the same component repeatedly with minimal variation. This consistency reduces waste, saves time, and guarantees quality across large production runs.

Efficiency is another key benefit. Modern precision machining allows for faster production without sacrificing quality. Automated processes reduce the need for manual labour, cutting down on human error and speeding up production timelines.

Furthermore, precision machining contributes to cost savings in the long term. Although the initial investment in equipment and software can be high, the reduction in material waste, labour costs, and rejected parts provides a strong return on investment.

Technological Advancements in Precision Machining

The field of precision machining continues to advance rapidly thanks to innovations in technology. CNC machining remains the cornerstone of the process, but new developments such as multi-axis machining and additive manufacturing are pushing boundaries even further.

Multi-axis CNC machines can move tools along multiple directions simultaneously, allowing for the creation of complex geometries that would be impossible with traditional 3-axis systems. Meanwhile, combining precision machining with additive manufacturing (3D printing) enables hybrid production methods that maximise both speed and accuracy.

Automation and artificial intelligence are also transforming precision machining. Modern systems can monitor performance in real time, predict maintenance needs, and optimise cutting paths automatically. These innovations ensure not only improved quality but also enhanced productivity and reduced downtime.

The Importance of Skilled Technicians

Even with the rise of automation, skilled technicians remain essential to the success of precision machining. Operators and engineers must have a deep understanding of materials, tooling, and computer programming to achieve the best results. Training and experience are crucial in ensuring machines operate at peak performance and that each component meets its intended design.

Sustainability and the Future of Manufacturing

As environmental concerns continue to grow, manufacturers are placing greater emphasis on sustainability. Precision machining contributes to this effort by minimising material waste and improving energy efficiency. Advanced software can calculate the most efficient cutting paths and optimise resource use, reducing the environmental impact of production.

The future of precision machining looks promising, with continuous innovations enhancing accuracy, sustainability, and cost-effectiveness. The integration of AI, robotics, and digital monitoring systems is expected to drive even greater efficiency across industries.

The Next Evolution of Precision Engineering

Looking toward the future, precision machining is set to become even more integrated with digital manufacturing ecosystems. Through smart factories and interconnected equipment, data collected from each machining process can be analysed to enhance efficiency, reduce waste, and predict future maintenance needs. This data-driven approach not only increases output but also creates a feedback loop that continuously improves quality control.

The growing use of sustainable materials and energy-efficient tooling is reshaping how manufacturers view productivity. Lightweight alloys, recycled metals, and advanced composites are now being machined with unprecedented accuracy, helping reduce both environmental impact and production costs.

Furthermore, collaborative robotics (cobots) are emerging as key partners in precision machining facilities. These intelligent systems assist human technicians in high-precision tasks, blending human judgment with robotic accuracy.

Ultimately, the future of precision machining lies in its ability to combine automation, analytics, and environmental responsibility into one seamless process. Companies that embrace this transformation will not only enhance performance but also drive innovation across industries, building a more efficient, sustainable, and precise world of manufacturing.

Conclusion

Precision machining is more than just a manufacturing technique; it is the foundation of modern industry. Its ability to produce high-quality, reliable, and intricate components ensures that everything from cars to medical devices functions safely and effectively. As technology continues to evolve, precision machining will remain central to progress, setting new standards for excellence in manufacturing.

For businesses looking to achieve exceptional results, partnering with experts in precision machining offers the accuracy and reliability required for success. Whether in aerospace, automotive, or healthcare, the value of precision machining lies in its ability to turn complex designs into flawless realities.

Imagup General Magazine 2025

Imagup General Magazine 2025