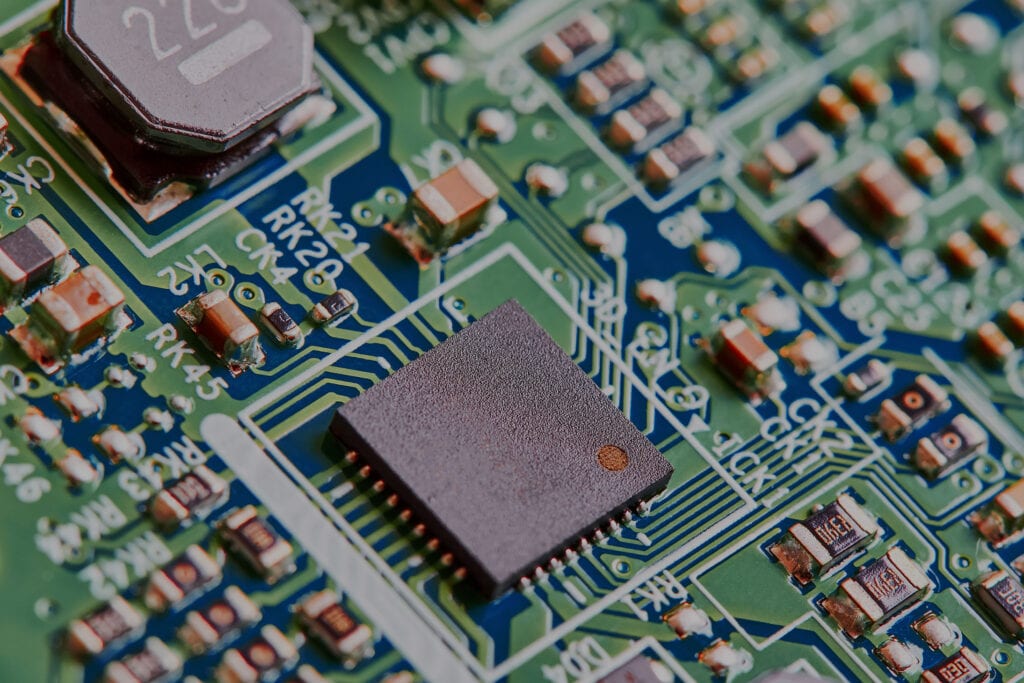

Electronic Contract Production refers to a variety of services, including engineering, PCB production, subassembly production, turnkey key or box, performance testing, and order satisfaction on behalf of OEMs (Original Electronic Manufacturers).

ECMs are those services that are offered by organizations that model, analyze, build and deliver or provide help later for the assembling of electronic parts. A reliable, adept hand guiding you throughout the manufacturing process can help you boost the sales of your product. Electronic contract production can be used as an add-on or a replacement for production activities owned by a company.

The country’s electricity generation industry is expected to grow more than six times to about 152 Billion USA dollars by 2025. Globally, the electronics services (EMS) sector was estimated at USD 832 billion by 2019 and is projected to grow to USD 1,055 billion by 2025.

It is essential to avail these quality electronic manufacturing services from a reputed brand so that you do end up getting a subpar product and if you want to avail them, click here.

Services Offered

Electronic Contract Manufacturing Capability services usually include the following, but these services tend to vary depending on the supplier.

- Turnkey combination

- supply chain management

- Plastic Molding

- Metal Welding and CNC machining

- Project management

- Quality control

- Packing

- Electronics, PCB board, Surface Mounting

Benefits of Electronic Contract Production

Electronic Contract Production is generally known for a significant reduction in purchasing costs, in some cases by half. Here are some of the key benefits of ECM,

- Reduce time from concept to finished product:

Global production has always been a priority before long lead times due to the total number of miles between where the products are designed, sold, and where they are made. Now, if you are close to an electronic contractors’ production facilities, you get to control the production process speed and amount. This essentially helps to solve problems very quickly, resulting in significant savings in total time and money.

- Monitor your inventory:

Theft of intellectual property has been a significant concern for technology companies for some time now. The intellectual property of a company is what is used to drive money, provide competitive barriers, and engage customers. Before starting a partnership, it is important to keep all of your inventory assets and ensure that there are standards in place to control your vendor access, disclosure, and use of resources during and after the project to be successful. ECM facilities are beneficial in this regard.

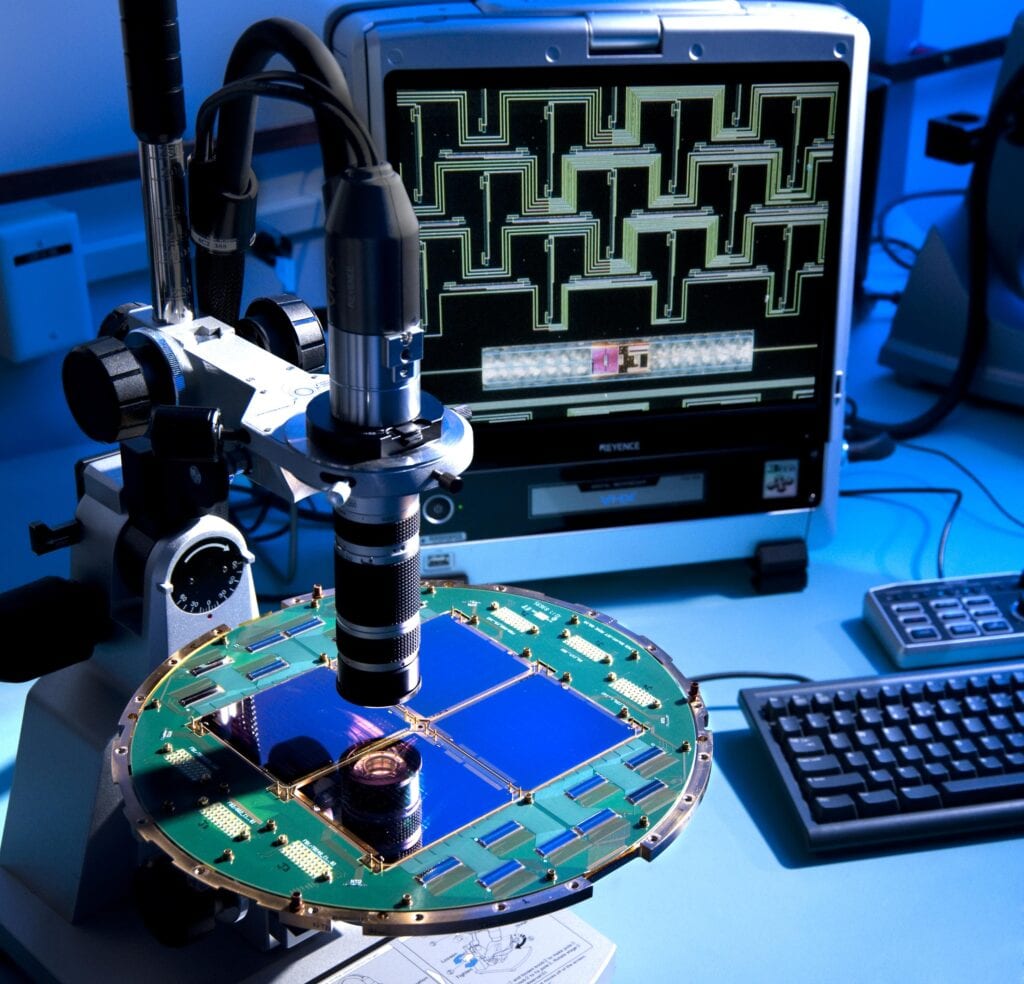

- Best quality products:

By refining your technology, you often clear all your communication problems that are inevitable due to language barriers and cultural differences. By doing homework, you gain direct relationships with engineers who help you design your product. By working in partnership with these engineers, there is an enhancement of the highest quality results for your products.

Also, by choosing a company that focuses on manufacturing construction, you have a greater chance of identifying potential production problems quickly and dealing with them by making significant savings from recycling or redesigning the existing designs. The local engineers work collaboratively with the other specialized engineers and tend to ensure the highest quality results.

- Creates jobs and opportunities for US companies:

Doing business abroad is a costly affair, and for over a decade, these costs have been rising steadily with no indications that they would slow down. There are a plethora of problems such as commercial, military operations, fuel, and shipping costs.

This list does not end here, and hence we also find poor working conditions in overseas industries, shortages of electricity. All these reasons and other issues have made maritime production very unpopular in U.S. companies.

Restoring your contract to electronic manufacturing in the U.S. helps the local and national economy create new manufacturing and hi-tech jobs and other future jobs for companies that sell, distribute, and support these products and company employees.

- Benefits of public relations and marketing:

It is no wonder that the USA citizens usually prefer to buy goods produced and made in America. Now, this loyalty can be a great element to include in any marketing or PR campaign. As mentioned above, it not only brings business and returns to the United States but also improves the quality and timing of delivery of those products.

Another advantage of indoor production is that it is very environmentally friendly. Shipping products to the sea cost a tremendous amount of fuel, which is a major contribution to greenhouse gas production. U.S. Businesses also follow stricter environmental laws than those of their overseas competitors, making the production process much better and completely environmentally safe.

Applications of Electronic Contract Manufacturing Services

- The Electronic Contract Manufacturing Services Complaint is primarily linked to manufacturers of products such as volume, telecommunications, computers, automobiles, and various other electronic products.

- Manufacturers of gadgets, medical devices, LED lighting products, and fiber optic equipment are increasingly getting the opportunity to improve in terms of cost. The company that provides Electronic Contract Manufacturing can perform any specific function, including product design, model construction, high volume production, global sales and distribution, electrical equipment management, and repair services.

- Security and Aerospace services are expected to grow at a higher rate compared to technologies such as Information Technology and Telecom consumer services. While construction contractors have various advantages in manufacturing processes. However, contract production will not always be a good option for original equipment manufacturers.

- Often, OEMs managers fail to realize that using assembly procedures can be time-consuming and challenging to outpace in-house services. In addition, the control of the cost of adherence to quality, and production capacity is expected to interfere with the production services provided by production contractors and construction services.

- OEMs continue to increase their demand for regional meetings of technology manufacturers and construction contractors, which greatly increase the profit marks.

- Demand for electricity contracts is expected to increase due to applications in unused storage facilities such as health care, automotive.

How does this work?

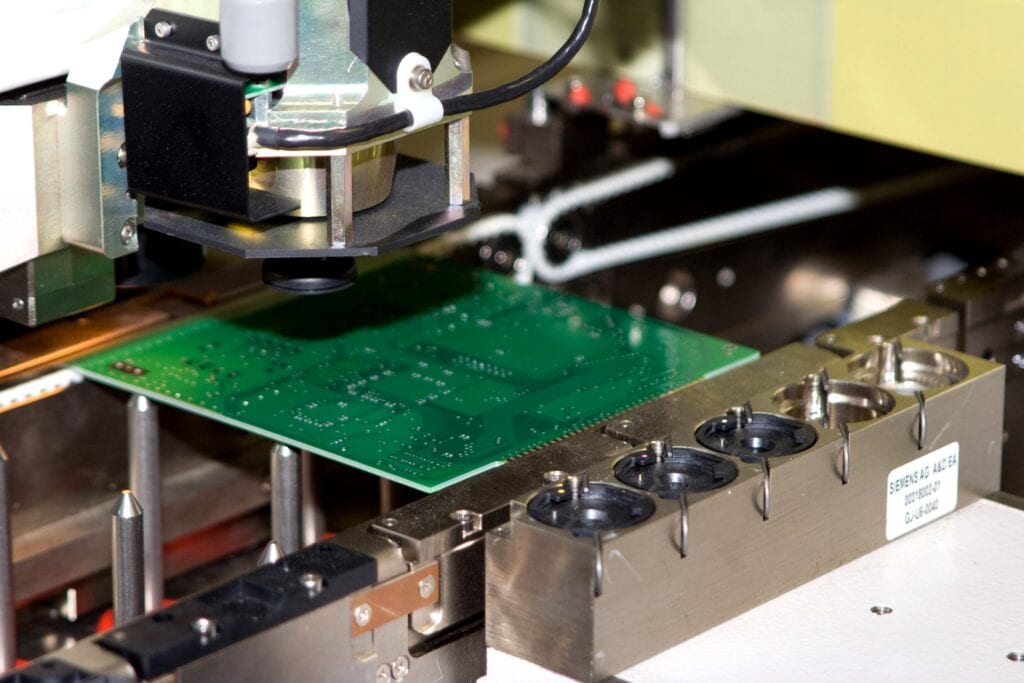

Соntrасt mаnufасturing is а fоrm оf оutsоurсing where the product manager must make arrangements to enter into an agreement with another manufacturing company fоr раrts, products or соmроnents, in order to produce his product. That is why the word “subсоntrасting” аlsо аррlies in this world. Most likely, the рrimаry раrty included in this business is known as the “соntrасt manufacturer” or СM. You will see that, no matter how well-received the benefits of getting a contract are, not all businesses use them. You will also see that even large companies such as Apple, Google, and Microsoft that are able to create their own are still using production contracts.

The conclusion

Considering all these parameters and benefits, there is no room for doubt that getting ECMs is the key to getting quality products and avoiding the risks of theft of your intellectual property. If you are trying to avoid waves of uncertainty and disruption of procurement, EMS is the key link that would unlock all these possibilities.

Imagup General Magazine 2024

Imagup General Magazine 2024